August 2007.

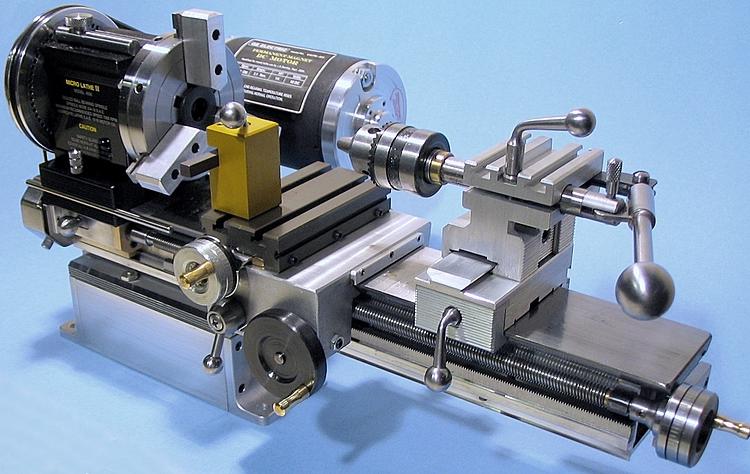

Here are some selected pictures of my present Taig lathe and modifications.

This lathe has many new additions and it has now replaced my original Taig lathe.

If you want to see more about Taig's new version of the cross slide/carriage assembly

Click Here

Click to see more about about the DC motor

I did a quick check of this lathe regarding the (spindle-to-bed-to-barrel) alignment.

Leadscrew:

Click to see more about my

Taig leadscrew

Lathes

(The identical lathe that this one replaced in 2007 is alive and well and shows few signs of its twenty-two years of use.)

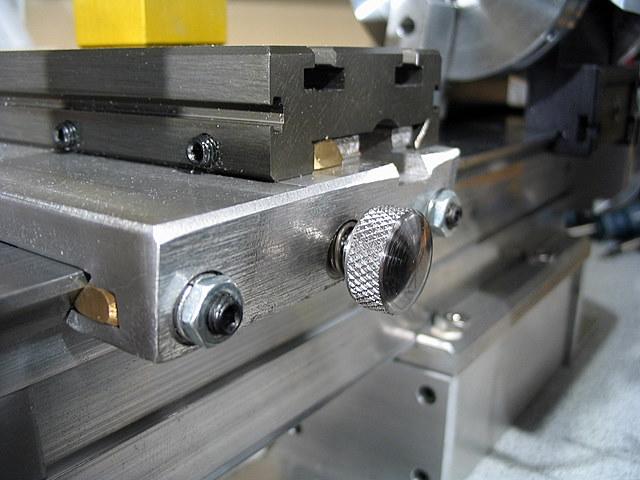

Raising the Taig foot by two inches makes all the difference in using the carriage handwheel smoothly

(and it doesn't hurt the ability to clean underneath either!)

A decent drilling lever allows more pressure to be used without increasing its length

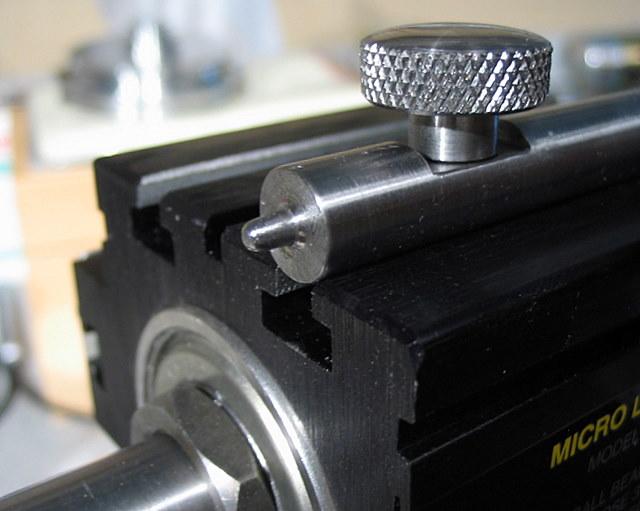

A knurled handle on a removable split pin

This is the half-nut actuating lever on the front of the apron.

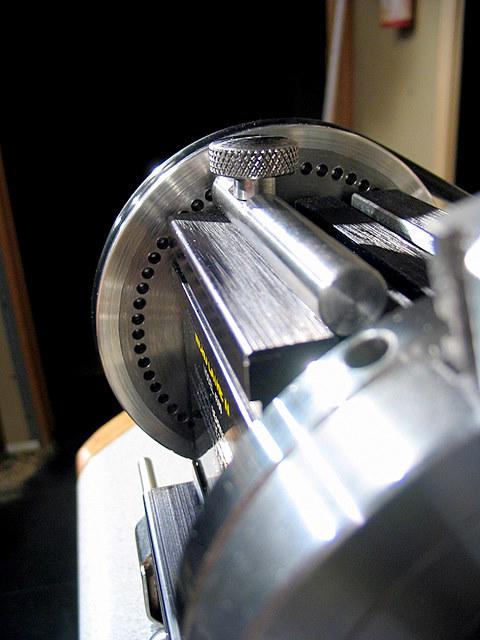

Locking pin for the 60-hole division plate

I made the flattened area large enough to handle traditional flat-type thumbscrews, or my knurled knob

Not much space for fingers, so I made this tall triple-knurled knob for a good grip - it works fine!

(you can see the stainless carriage stop rod in the slot)

Taig uses flat blade thumbscrews for the carriage stop rod, as well as the carriage lock....

(I replaced them, including this one at the back of the saddle with this homemade knurled knob of 12L14 and added a coil spring to prevent it from vibrating loose)

Well!

- things have a way of changing!

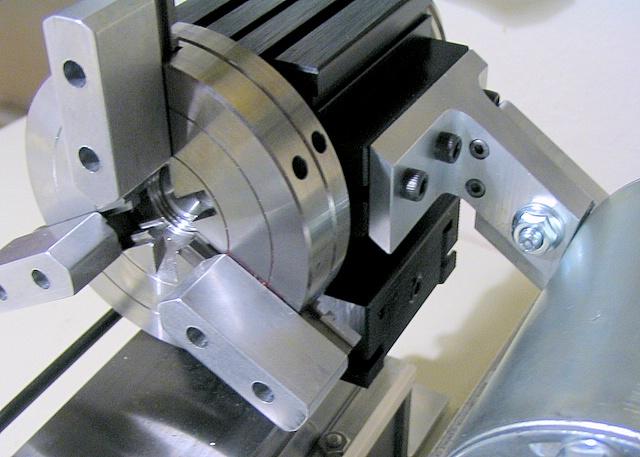

The new Taig headstock rear T-slot provides an excellent place to attach the motor

(a 4x6 bandsaw was invaluable in making the angled bracket)

Adding leather bed wipers to the old-style carriage saddle

If you are curious how a typical Taig lathe stacks up - out of the box -

look here

Click for some photos of the innards of the Dog-type Clutch

The clutch body is bronze with an aluminum faceplate

(there is a flat sliding strip inside the slot to keep out foreign material)

Note also that I have replaced the stock steel carriage stop bar with a rounded

stainless steel version.

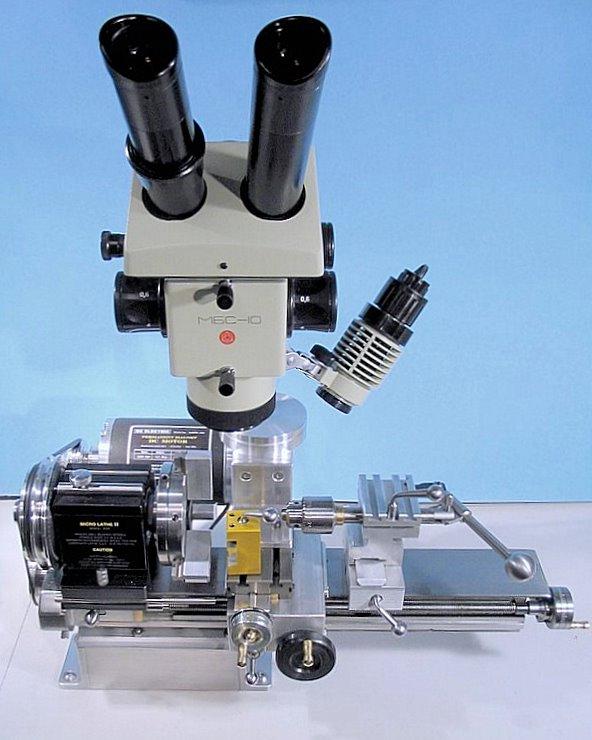

Here is a new addition. It is amazing how clearly small work can be seen while turning!

About the microscope

About attaching it to the Taig

Workshop

Back to the ModelEngines.info

home page