October 2008.

A Quick Check of the Alignnment of a New Taig Lathe

(This is not intended to scare anybody off, but rather to show that the alignment of an "off the shelf" Taig is pretty darn good - even down to minute figures and therefore should be far beyond that required for normal size model projects)

HEADSTOCK:

The essence of this test is to place a uniform round bar in the chuck, unsupported at the tailstock end and then determining the location of the axis around which it rotates at two points along the length of the bar.

Only the precise location of the lathe axis needs to be determined for this test. Inevitably the bar will wobble slightly at the far end, but this is of no importance as it will cancel itself out in the calculations. It is simply a matter of determining the mid-point between the highest and lowest readings (using simple arithmetic) then comparing with a mid-point similarly derived at some distance down the bed.

Finally, a second test was done in the vertical plane by measuring along the top of the bar to determine the parallelism with the bed. Error here has less effect on accidently producing a slight taper when turning a long bar since the tool cuts from the side, not the top. Out of the box, my lathe was only off by a fraction of a thousandth over a length of five-and-a-half inches in the vertical plane. Anything under one-thousandth for every inch is tolerable, but most people try to do a little better than that - so I'm sure not complaining! My headstock is not shimmed and I bought this particular lathe over-the-counter from Lee Valley Tools.

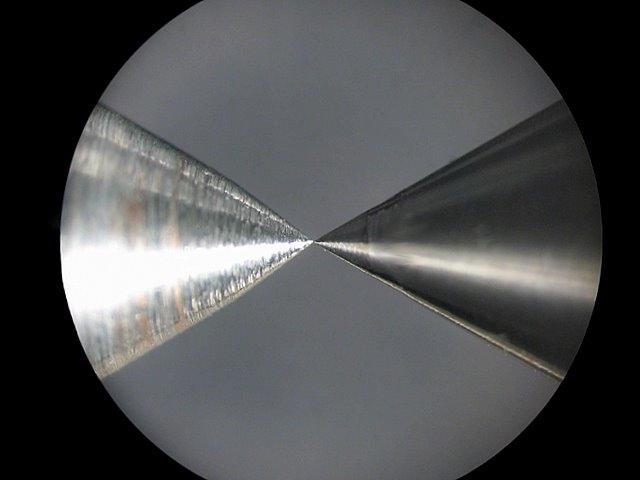

Using the microscope to view the center tips while adjusting the tailstock set-over slide

Consider that this represents the combined inaccuracies of the headstock, bed, tailstock (dovetails, bore and center), as well as the drill chuck and bit.

The total is off by 0.35/20 mm - that's less than 0.0007" (even the drill chuck alone could account for this much error - typically they aren't rated at anything like that degree of accuracy).

Back to the

Taig Lathe

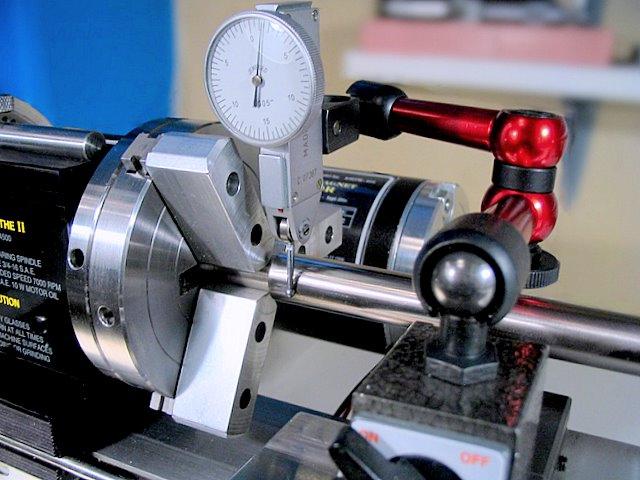

(I have attached a steel plate from another accessory to the aluminum cross slide so the magnetic base will get a grip)

Ideally these points will be an identical distance from any common point on the carriage, no matter where the carriage is located along the lathe ways. Fortunately the dial indicator is able to compare those distances effortlessly.

if you get a chance to pick up one of those single-knob dial holders - they are fabulous !

TAILSTOCK:

After it was determined that the headstock spindle was pointing straight down the bed, it was time to check the set-over adjustment on the tailstock. I put a center in the headstock and refinished it to ensure zero runnout of the tip. The tailstock center was brought up to the headstock center to view the accuracy of its height as well as its position in the horizontal plane. The latter can be adjusted by the tailstock set-over slide.

I did this test both with the tailstock ram retracted and fully extended. The results were the same, indicating that the tailstock bore is well aligned with the spindle axis - at least with the tailstock clamped at that one position on the bed. The earlier tests proved that the bed ways and spindle axis are in agreement. Therefore it is logical to conclude that the same is true of the tailstock barrel axis, since the tailstock uses the same bed ways as the carriage.

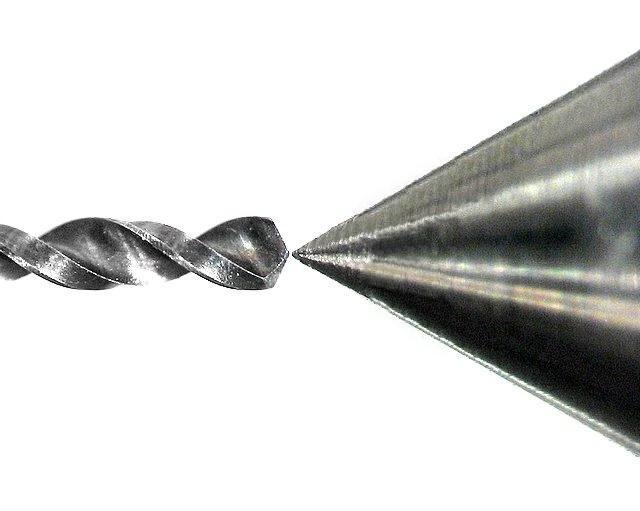

When I look at a view like this, I throw all those dial indicator numbers out of my head because...I just know that drill is pointing in the right direction!

To keep the record straight, this is the Jacobs 1/4" commercial quality chuck as supplied by Taig

The following pictures are magnified, but it is the same chuck as above

This drill shank is 1 mm and the micro drill section is 0.35 mm

The same micro bit as above, mounted in the drill chuck with the tailstock center fully extended

(under considerable magnification try looking at the last three pictures again!)

ASKING A LOT: checking the chuck alignment while using the headstock drill chuck arbor

A close-helix 3/64" bit pointing at the tailstock centre

That pretty well covers the most important tests of the basic alignment of this small lathe.

If you don't have a life, you could measure the top of the cross slide to see if it is parallel to the bed ...or perhaps you could calculate the speed of light if you don't believe Michaelson... Similarly, I doubt very much if it is worth measuring the flatness of the bed. There are however a couple of other tests that I conducted, one of which was quite revealing.