© John R. Bentley 2009.

October 2009.

Testing Lathe Bed Rigidity

Mini Lathe vs Taig

Originally I wanted to test the lateral play in the headstock bearings after re-adjustment on my Craftex 7"x8" mini lathe. I decided that while I was at it I should check out my Taig bearings as well.

Please note that these checks were done against the inside of the spindle tapered wall in each case. The taper angles are different for the two lathes and this tends to make the Taig exhibit more play than the Craftex. In any case the effect these tapers have in this discussion is insignificant. The facts are that in the first test the results were quite similar for the two lathes and in the latter test they were very different.

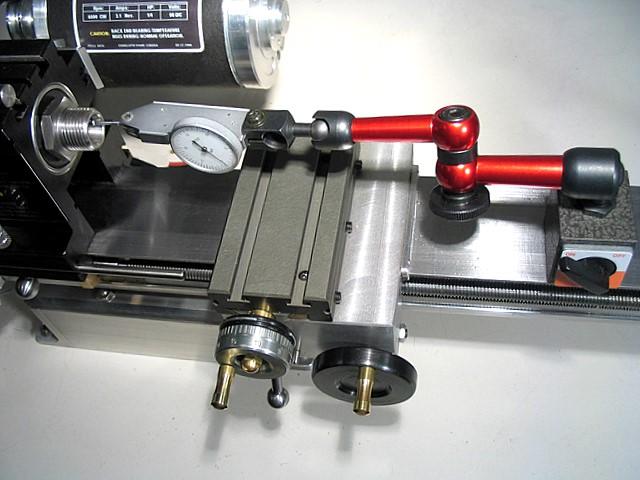

In the spindle bearing tests both lathes were essentially perfect - less than 1/5000".However I then decided to use the setup below to measure the comparative bed rigidity on the lathes. I attempted to twist the rigid cast iron bed of the Craftex lathe by "push-pulling" the headstock against the tailstock with my hands. Those results might surprise some people.

I was able produce a deflection of 2½ thousandths along an eight-inch length of the bed.

Eight-inch distance from the indicator tip to the magnetic base

I used the same eight-inch measuring distance on the Taig

Using considerable force I could only produce a deflection of one-half of a thousandth!

Note that the Taig is a mere skeleton of a thing - with motor it weighs about 25 lbs while the Craftex is massive for its size at 77 lbs.

You might argue that the mini lathe will naturally exhibit a little more twist due to the center height being 3.5" instead of the Taig's 2.25" center height. True.....but in using the lathe that doesn't matter - if you are turning the same diameter piece, the mini lathe will flex five times as much and inflict five times the surface damage.

* I should note at this point that the Craftex mini lathe used in this test has the same bed design and material as the 7x10 and 7x12 mini lathes except it is shorter - and presumably stiffer.

Perhaps this is where the myth started about mass in the machine being the "only" solution to good finish. Due to inertia, a massive headstock and carriage will resist quick movement and vibration that is due to a "rubbery" cast iron H-section bed, but isn't it simply a giant band aid solution to a basic design shortcoming?

On the other hand, a very rigid bed would make gross amounts of mass unnecessary. In other words, proper design would eliminate the problem and make for a more efficient machine weighing a fraction of the others and allowing better control of the carriage and slides, meanwhile producing a better finished product.

It goes to show that there is more to the Taig design than meets the eye. I believe it is the special "concrete" inside the extruded aluminum bed that makes the difference. To think, there once was a company competing with Taig using the advertising attack slogan, "when aluminum won't cut it..."

Just to clear up a couple of things:

I am not against using mass to my advantage when machining - I only object to using it as part of a convoluted argument. For example I have a very massive bench vise which I use to file and saw tiny objects by hand. I truly believe this is one of the secrets to successful hand sawing and filing. The mass of the vise holds the work steady as each tooth cuts, instead of allowing it to be displaced only to bounce back and set up a vibration thus interfering with the quality of finish.

I have no quarrel with the Asian mini lathes - I use my Craftex version on a regular basis, but it never seems to provide the same fine surface finish on the work that the Taig delivers routinely. This is true of both my Taig lathes - my 20 year old version and my new one. The bearings on my Craftex mini lathe are snugged up and the slides are adjusted well, so I can only attribute it to less bed rigidity. That's hard to prove - I can show the comparative difference between the mini and the Taig, but can't prove exactly what that amount of flexing does to the finish quality on different materials.

To be clear, I use my Craftex mini lathe as much as my Taig when constructing miniature engines. The mini lathe has some capabilities that are difficult to find in a Taig, but the Taig can do things that are more difficult to achieve using a mini lathe. These machines are both suited to a similar size range and within that range, good work can be coaxed from either by simply relying on good procedure - and not expecting the machine to do your part of the work.

Some free advice!

It's great to take on "pseudo-snobbery" about how one or the other of these is machines not able to do some certain job, but I think in the long run we are fooling no one but ourselves. If we can't figure out how to do something, it doesn't mean it can't be done - it just means we don't know how to do it.

Join a good forum, ask for suggestions and learn how to separate the good answers from the bad - it's not that difficult! Machining procedures aren't big secrets. There is a lot of knowledge available - and people who have it are only too happy to help. I have appealed for assistance on the web many times and never been disappointed.