August 2007.

Taig Lathe 90 Volt DC Motor

Many people have asked me about the type of motor I installed on my new Taig, so perhaps this page will address some of those questions. It was modified slightly for sealing and cooling purposes.

Back to the

Taig Lathe

I applied a high temperature silicone coating to the motor shell

This provides a more unified appearance to the lathe. I used a flat black coating, sprayed to produce a very slight "pebbling" and buffed the surface after it set to provide an appropriate and durable surface.

The armature is a good size and up to the task

Here is a closer look at that front bearing

The rear bearing is quite different. It is a self centering bushing

The graphite brushes seem amply proportioned

Nice thick shell

Aluminium foil will be packed between the outer cap and

the bearing protrusion on the motor's steel cap underneath

(it provides faster thermal conduction from the bearing)

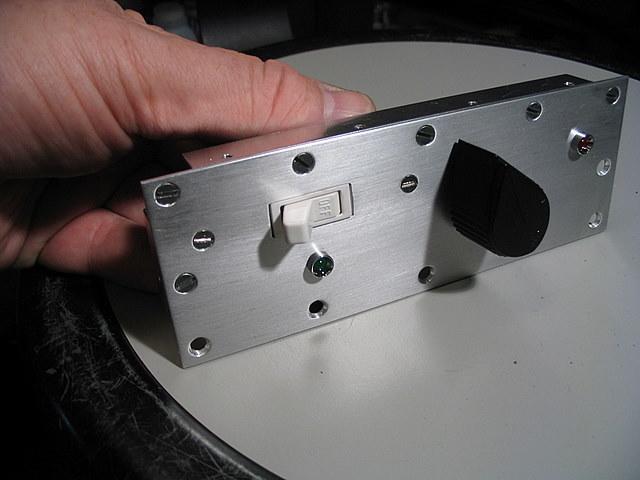

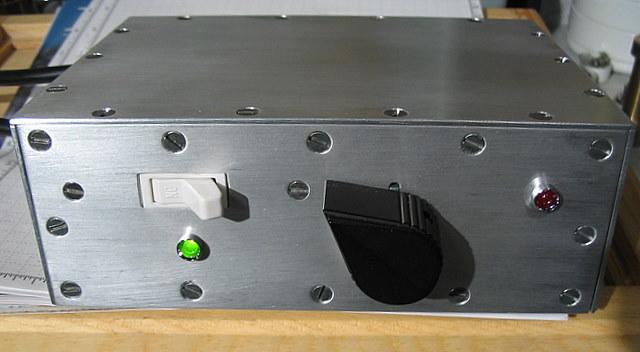

These images show the same motor in its original livery

Here is the stamped steel back endplate

My new aluminum heatsink/endplate is simply pulled tightly against this by the long bolts

Here it is under construction in the milling machine

How did I get that smooth finish on the front plate?

Simple!

The PWM motor drive