BOX BED AND SOLEPLATE CONSTRUCTION

for the Naval Brass Vertical Engine

© John R. Bentley 2005.

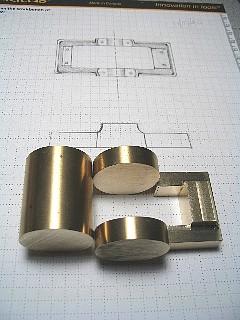

Here is the raw material that made this engine. This is a piece of a 1½" discarded propeller shaft.

Years of wear and surface corrosion from a former life are being removed in the lathe.

The soleplate, or main base, was fabricated from sections cut from the shaft.

The picture to the right shows all six parts made from the cylindrical pieces.

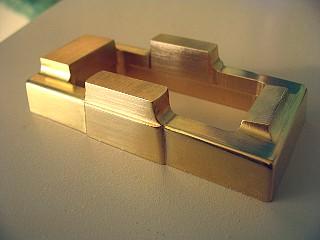

The components were silver brazed to provide a base that is at least as strong as the individual pieces.

Things don't always look all that pretty immediately after silver brazing!

When different shapes are required, the 4" x 6" bandsaw, in vertical mode, comes in to play.

That old brass even looks like a log!

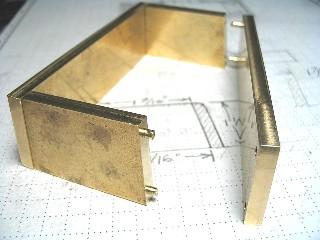

The box bed is being constructed to hold the soleplate high enough to provide clearance between the bottom of the flywheel and the floor.

It also serves to form the engine crankcase.

Although it doesn't show in these photos, the sides actually lean in slightly toward the top in this design.

This necessitated using the pins to hold it together properly for the silver brazing job.

A little cleaning does help!

BACK