John R. Bentley 2006.

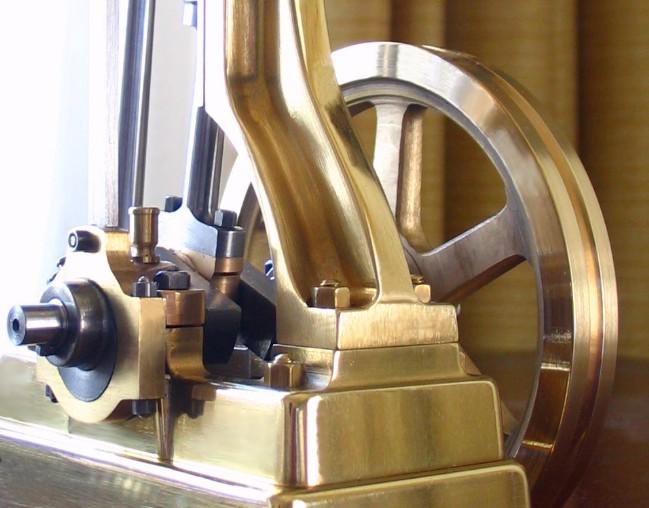

A Naval Brass Steam Engine in Half Scale

- A SCRATCH-BUILT TRIBUTE TO MR. TURNER'S "OLD No. 1" -

Over a hundred years ago, Stuart Turner designed his No.1 Vertical Steam Engine. The beautiful proportions of his design have been admired ever since by generations of steam enthusiasts, professional and amateur alike.

The cast iron prototype engine is quite large, standing thirteen inches tall and wielding a 7½" flywheel. I thought it would be fun to fashion a near-copy in half scale without plans - working only from a picture of the original engine. To add to the challenge, instead of using cast iron, I decided to use a 1½" propeller shaft from a lobster boat and saw it into "brass lumber" for the project.

The material is Naval Brass. It is hard and slippery to machine, with a machineability factor of 30, compared to 100 for free-cutting brass. However when a job is done in this metal, you have something! It is both durable and attractive. I find cast iron and steel much more pleasant to work, and could have saved some time, but I own other engines of painted iron. This one was to be different.

All the brass parts were fabricated by the silver brazing process, using this recycled Naval Brass. Cast iron and two types of steel were used where appropriate. The piston, main bearings, glands and drain cock bodies were fashioned from 660 Bearing Bronze. The piston rod is stainless steel.

A note:- Nearly fifteen years after working on this project I learned that the Stuart Turner company did something similar in the early 1920's. A half-size simplified version was released as the No.10 Engine for about eight or nine years. This was different from the later (current) 10V engine. However to lighten the demands of construction for amateurs the model was noticeably reworked after that period. The single column and crosshead slide were removed from the miniature version considerably altering its apperance. These components were replaced by a one-piece double standard and tunnel crosshead. Still very attractive this version was first referred to as the "New No.10", now simply known and sold as the popular Stuart 10V.

The wheel pictured below was totally constructed from a 1½" diameter lobster fishing boat prop shaft.

It required ten separate pieces and construction spanned thirteen days.

(OK, that's not the only thing I did during those thirteen days!)

FABRICATED FLYWHEEL

The subtle color of the spokes was created by gently sandblasting the brass with a tiny and inexpensive hobby sandblaster which resembles an airbrush.

THE BIG END (the hardware is 2-56 tpi)

A WORM'S EYE VIEW DURING CONSTRUCTION

GOOD OLD-FASHIONED POWER

I have taken many other pictures during the construction of this project.

If you would like to see more:

See TEN CONSTRUCTION pages.

OR

Return to ModelEngines.info Homepage.

© John R. Bentley 2005.